THE

MOLECULAR

DANCE

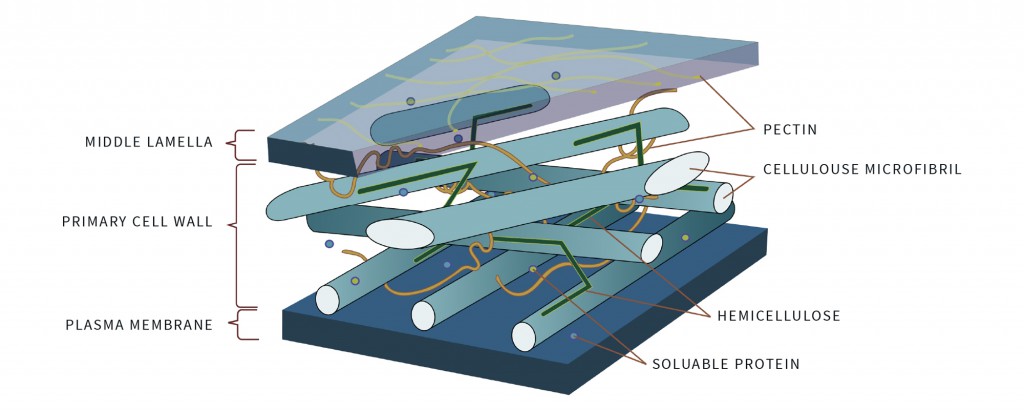

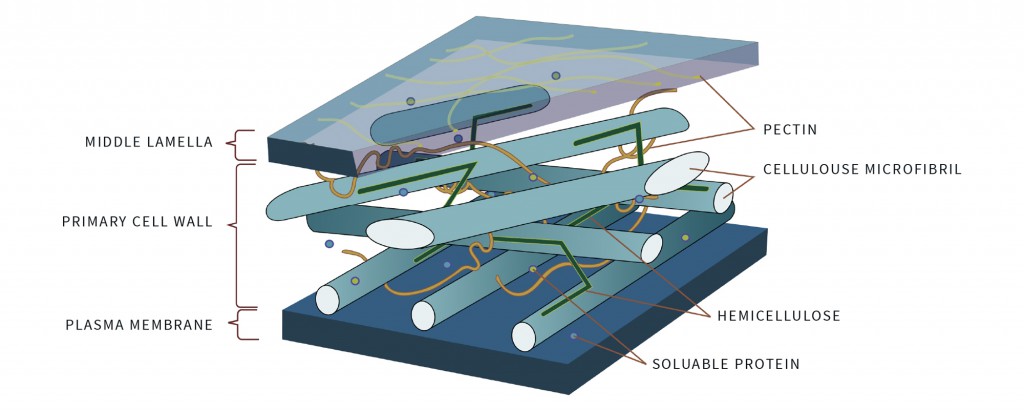

PLANT CELL WALL DIAGRAM

Licensed under Public Domain via Wikimedia Commons

There are five primary chemical constituents

in the Oak which effects whiskey maturation;

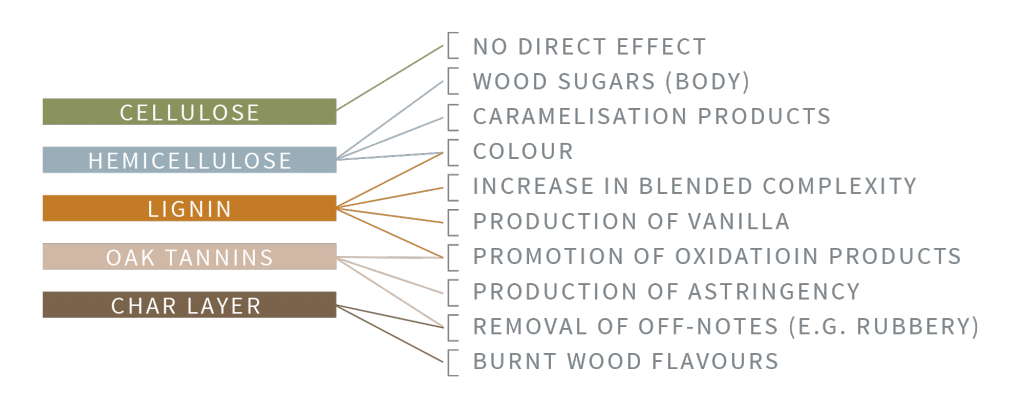

1.CELLULOSE

As the name suggests, this compound is primarily composed of a form of glucose (sugar). Despite this, it does not impact on any notable flavour elements in a mature spirit, but instead acts as a binding agent or polymer to help hold the wood together. (i.e. essential in oak’s ability to hold a tight cooperage). It is so effective at its job that it is the most abundant polymer in the natural world.

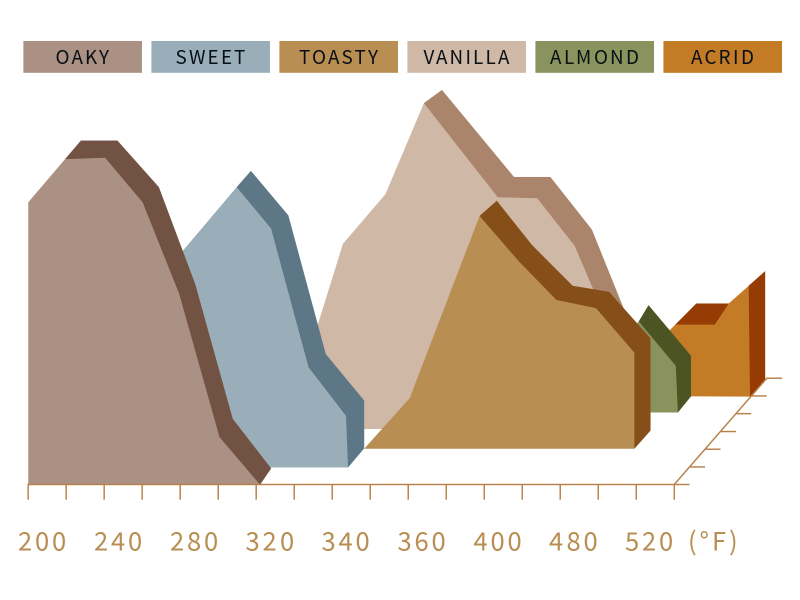

2.HEMICELLULOSE

While also a sugar based polymer, hemicellulose is not solely composed of glucose like cellulose but of multiple sugars such as glucose, xylose, mannose, rhamnose, arabinose and galactose. Most importantly, these sugars are much more unstable than glucose, allowing them to breakdown into their individual parts when stimulated by dramatic changes in their environment, such as heat. In these newly activated hemicellulose sugar condensation by-products (furfural, Hydroxymethylfurfural, maltol and cyclotene) which ultimately give us the deep brown colours and subtle almond, walnut, butter and maple notes from a lightly toasted cask. When the heat is turned up even higher to the levels of charring, most of these flavours are pushed aside by rich caramel and toffee. For hemicellulose to begin converting into colour and flavour, it needs to be activated by a heat of at least 140°C (284°F) which is why we flame-char the inside of each cask.

3.LIGNIN

Anywhere there is a hardwood, there is lignin. While also a polymer, lignin is composed of two core structural parts; guaiacyl and syringyl. It is the direct result of these combined parts which is responsible for giving us sweet and spicy aromas, especially vanilla, which is pulled from its chemical namesake – vanillin. Lignin congeners can be released very easily with only the smallest amount of activated heat, however it is the effect of heavy toasting and deep charring which breaks down the lignin further into steam volatile phenols, responsible for delivering smoky flavour elements.

4.TANNIN

As the name suggest, it is from tannin we first derived tanning agents for leather and early dyes, giving us the common word ‘tan’. While there are many different sources of tannin in the natural world (such as grape skins), oak tannins are unique in that most of them can be broken down by not by adding heat, but simply by adding water. For this reason, oak tannins are classified as hydrolysable.

Acting primarily as a means of food storage for the tree, tannin help to protect it from fire and bacteria, evolving into a natural, bitter deterrent to insects in a similar way to the coffee plant (Coffea) produces caffeine as a bitter pesticide. As a hydrolysable compound, seasoning is used to remove large amounts of bitter tannin from the oak prior to cooperage. That said, we still need a small element of tannin to supply us with oxidization and fragrances like cooked apple. More importantly, however, is the role tannin plays on long maturation. The wood chemicals react slowly with oxygen molecules in the spirit over time, creating new compound called diethyl acetal. This new compound ensures that whiskeys of ten years and more such as HYDE are left with rich and complex top notes and are never flat and insipid.

5.LACTONE

Unlike the above components, lactones are released in the first year of aging and as such are more important to the brand new American whiskey barrels. Neither a polymer nor a sugar compound, lactone is a flavour element influenced by certain oils, soluble fats and waxes simply known as lipids which deliver a unique coconut-woody taste to a spirit. While present in all types of oak, lactones are found in their greatest quantity in American White Oak (with the exception of the rarely used Asian variety Quercas mongolica), releasing almost all of its flavour attributes in the first year of a first-fill barrel’s maturation. For this reason, Bourbon, Tennessee and Rye whiskeys all have outstanding vegetal characteristics when compared to Irish whiskey, which depends more on sweet, smooth polymers for flavour. Well-seasoned and lightly toasted casks can release further amounts of lactone when deep alligator charring can react the other way, reducing its effect.

It is well recognised that up to 80% of any final whiskey taste is as a direct result of the interaction between the maturing ‘new make’ whiskey and the wooden cask in which it is aged.

It is well recognised that up to 80% of any final whiskey taste is as a direct result of the interaction between the maturing ‘new make’ whiskey and the wooden cask in which it is aged.