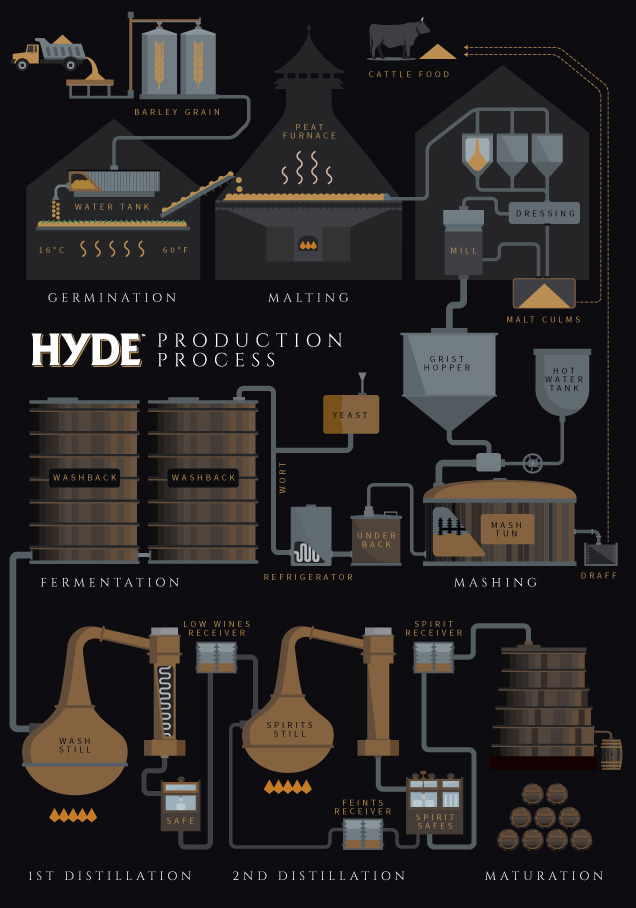

SINGLE MALT

HYDE Single Malt Irish whiskey is made from 100% malted barley grain from one distillery source in Ireland. It is double distilled in a traditional Copper Pot Still to our very strict HYDE specifications.

BARLEY

The Barley quality plays a very significant role in brewing performance. Barley quality can vary from year to year depending on the annual harvest conditions. For this reason barley selection remains crucially important when making a pure single malt Irish whiskey which is made using only 100% malted Barley sourced in

Ireland. The barley used to make HYDE Single Malt is sourced in Cork County. Cork is famous for its fertile soil, rich limestone which is ideal for growing Irish barley.

MALTING

There are three stages to malting barley; Steeping the grain in water; Allowing the barley to germinate and sprout, and finally drying the malted barley using hot clean air. No peat smoke is used when drying the malted barley for HYDE Irish whiskey, as would generally be the case in with most Scotch whisky brands.

MILLING & MASHING

To produce Single Malt Irish whiskey, barley grain is milled to create a flour called grist. In a large tub known as a ‘Mash Tun’ the grist is then added to hot Irish spring water and stirred to create the ‘Mash’. It is here that the conversion of starch to fermentable sugar takes place to produce a hot, sweet liquid known as the ‘Wort’.

Once all the starch has been converted into fermentable sugars, the wort is then drained off leaving behind the spent grain known as the ‘draff’. The draff is then sold to farmers who feed it to their cattle.

FERMENTATION

During fermentation distillers’ yeast is added to the sweet ‘Worth’ liquid. The yeast consumes all the fermentable sugars and in doing so creates alcohol and carbon dioxide. Once fermented, the wort is now called the ‘Wash’. This contains about 10% to 13% alcohol at this stage. Once it has been left to ferment for a period of three days, the wash is then transferred to the Copper Pot Still to distil off the excess moisture and produce the high strength alcohol.

COOPER POT STILL WHISKEY

Making whiskey in a copper pot still is the traditional Irish way of making Irish whiskey.

This traditional copper pot still produces the more complex flavour profile. One of the characteristics of a coper pot still whiskey is that it is more full bodied.

DISTILLATION

Distillation is the process whereby alcohol is separated from water. The wash is heated and at 78C Celsius the alcohol begins to vaporise. This vapour is cooled, collected and distilled for a second time. Hyde whiskey is double distilled to produce a more rounded ‘big’ whiskey with more character. We believe that double distillation is better than triple distillation when it comes to producing a single malt with a more robust character and spicy flavour.

MATURATION

After distillation the 80% ABV spirit strength is reduced with local filtered Irish spring water to between 60-70% alcohol and is put into handpicked oak casks and stored in a bonded warehouse to gently mature over time.